Service

With decades of experience in cable assembly,our R&D team provides a diverse range of solutions that tailors to the client's specific inquiry.

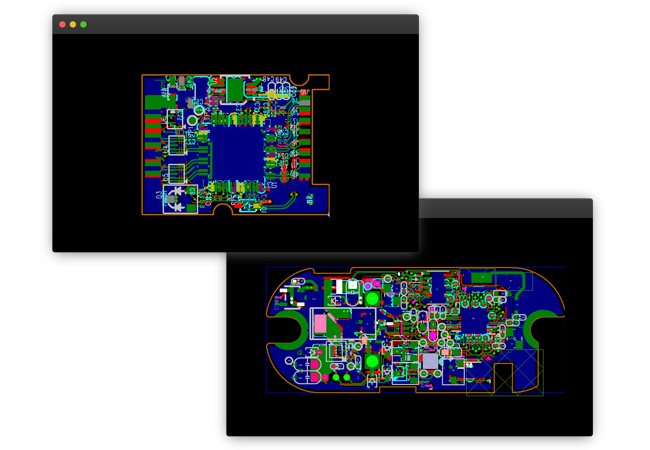

Aside from the cable design expertise, the company possesses engineering resources and equipment for

ODM & OEM technical support such as PCBA design,

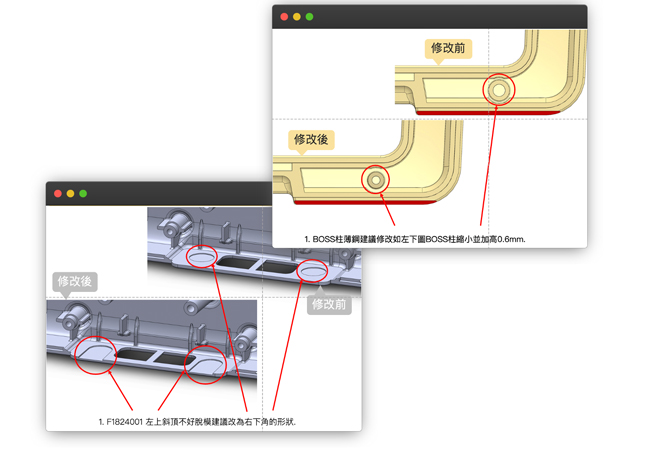

product structure, or tooling design.

As the product line diversifies, customer demand has also evolved beyond cable assembly.

The requirement of integrated services in electronic design and product assembly is more prevalent than ever.

Our electronic team provides more functional products by combining PCBA design and cable assembly.

Our ME team can diagnose and predict every product’s recessive flaws by proposing solution ahead of time.

Simplification Standardization and Modulation are the principles that minimize errors and maximize MP quality .

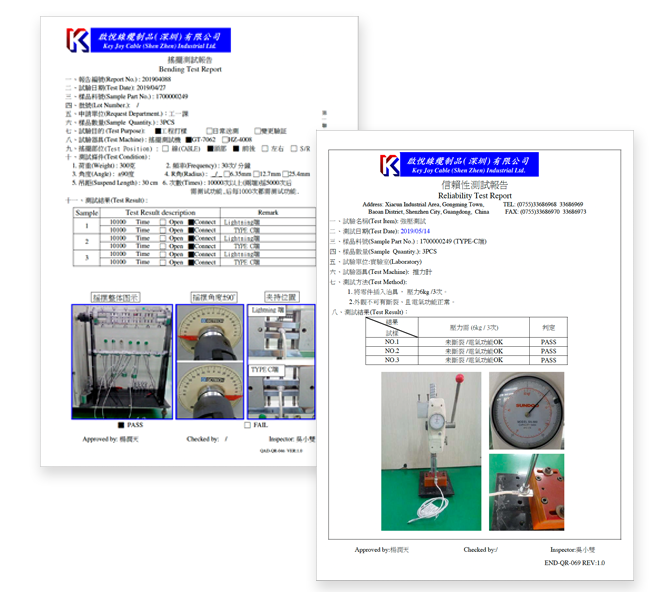

We can ensure the designed products operate in multiple utility applications reliably by providing a dynamic range of reliability tests.

The lab conducts various environmental inspections required for major automotive manufacturers with test equipment such as a thermal shock test chamber, programmable temperature & humidity chamber, X-ray, to name a few.

Comprehensive testing process and rigorous quality control,

it is the key to our success in the industry.

We choose the strategic partners with strict supplier assessment and vetting process.

Quality inspection before assembly to make sure the material fits the spec and remove any presented anomaly.

To ensure product quality, SOP must be strictly executed by the production team.

QC department checks for any defects before logistical fulfilment.

Provide multiple options for on-time delivery to designated locations.

The in-house sales team will assist the client with troubleshoots swiftly and effectively.